Launched in 2005, the 45L tax credit provides tax incentives to builders of energy-efficient homes in the U.S. Available on a year-to-year basis, the program has always existed with a level of unpredictability. It would all depend on if it were in effect.

Consequently, many builders have not taken advantage of 45L because they simply did not know if it was going to be renewed. It was difficult to react within a single calendar year and justify the added coordination and expenses if the program was going to end.

August 2022, President Biden signed the Inflation Reduction Act, which extended the 45L tax credits for the remainder of 2022 with new provisions starting in 2023. Beginning on January 1, 2023, builders of single family homes that meet the ENERGY STAR Certified Homes V3.1 (V3.2 in 2025) program 2021 IECC prescriptive envelope standards will be eligible for a federal tax credit of $2,500 per home.

The program will now run through 2032.

On a parallel path, builders who adhere to the Department of Energy’s Zero Energy Ready Home (ZERH) program can earn up to $5,000 back in tax credits per build.

If a builder applies these sustainable building practices across every home they build over the next 10 years, they set themselves up for major savings.

It starts by taking a holistic approach with even more attention to detail. The goal when planning and then building a home is to ensure all energy-saving measures are working in conjunction with one another to save costs and reduce the structure’s overall carbon footprint:

- Cooling equipment and air conditioning units.

- Heating equipment and furnaces.

- Building envelope insulation levels.

- Windows, skylights, and doors with appropriate U-values.

- Water heater equipment.

- Thermostat and ductwork.

- ENERGY STAR® lighting and appliances.

One of the key elements to executing a comprehensive plan is the materials chosen for the building envelope, particularly insulation.

The Importance of Insulation

Insulation is one of the most critical elements to ensure homes meet either ENERGY STAR or DOE ZERH requirements. Even the most efficient, effective heating and cooling systems are rendered useless without high-quality insulation in the walls, floors, and attic.

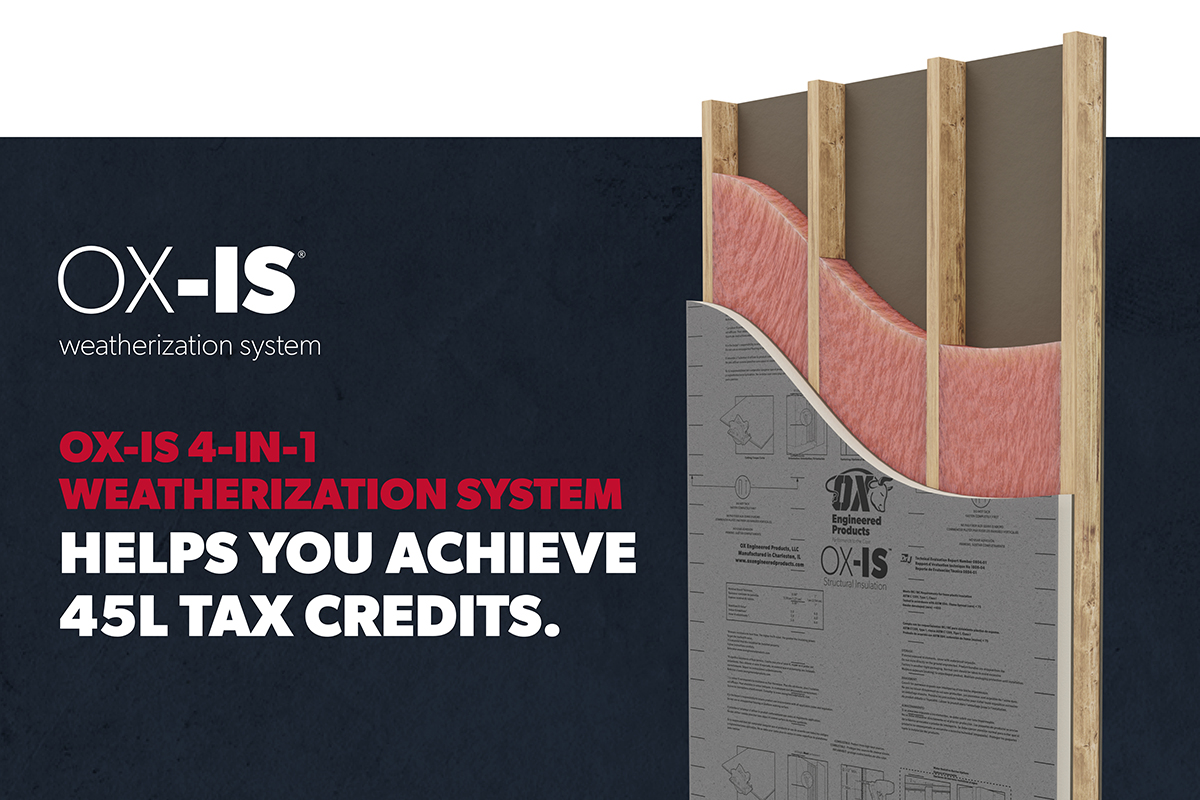

In fact, zeroing in on insulation as a builder can go a long way in earning tax credits. High-quality insulation, including products such as OX-IS, dramatically increases the R-value of an exterior wall. OX-IS is a 4-in-1 structural continuous insulation product that delivers the ultimate in thermal performance because it is installed outboard the studs continuously without a break.

In just a single-component, the OX-IS system does what it takes OSB, building wrap, and foam insulation boards combined to do. And OX-IS boasts a significantly lighter composition, remains more economical, and is a single-component solution. When OX-IS panels are installed with the appropriate OX seam tapes, the system provides a lasting best-in-class air barrier and a 30-year limited warranty.

Continuous insulation products that are integrated with a superior air and water-resistive barrier also contribute to a lower Home Energy Rating System (HERS) score. Not only does a lower HERS score boost the value of a home, but it points directly to its energy efficiency, thereby serving as a validated proof point for builders to earn the 45L tax credits. Having a HERS rater review the design can heavily contribute to a structure’s ability to meet energy use targets and eligibility for 45L.

Making More Homes Eligible

Consider this theoretical scenario for builders. If a builder follows the appropriate guidelines, incorporates a code-compliant ENERGY STAR air conditioning unit, and builds exterior walls with 1-inch OX-IS (R-6) and standard batt insulation, it could take their current total number of homes that qualify for the 45L tax credit from 15% to somewhere closer to 90%.

In this scenario, which builders can realistically achieve by swapping out regular sheathing for high-performance, integrated structural continuous insulation, they can increase the number of projects that they qualify for sizable tax rebates by a factor of six.

For someone that builds 100 homes a year and receives the full $2,500 credit per home, that’s $225,000 a year.

The Basics: ENERGY STAR and ZERH

There are two methods to achieve an ENERGY STAR Certified Home: The Prescriptive Path and the Performance Path.

The Prescriptive Path provides a single set of measures that must be followed to construct an ENERGY STAR Certified Home. Here, modeling is not required beforehand, but no product or system tradeoffs are allowed. Builders must follow the construction blueprint and build to an exact standard.

The Performance Path provides more flexibility to select a custom combination of measures for each home that is equivalent in performance to the minimum requirements of the ENERGY STAR reference design home. Equivalent performance is assessed through energy modeling.

For a DOE ZERH, the home must meet the minimum specified requirements set by the DOE, be verified and field-tested by an approved energy rater upon completion, and meet all other applicable codes. If local building codes exceed the standards set by the ZERH program, those local requirements must be met. Remember that the builder and the rater must both sign a DOE ZERH partner agreement for a home to become certified.

Why This All Matters

Rising utility costs and a dire need to preserve energy and protect the planet have given way to these types of programs that help combat climate change. The government and other leading energy organizations are working hard to carve a simpler path forward for builders and homeowners to benefit from sustainable building and living.

Therefore, building to ENERGY STAR and DOE ZERH standards is more important than ever. What’s more, the monetary benefits that can be gained from adjusting building practices to meet these specific requirements makes doing so an obvious choice. Plus, it does not require a complete overhaul to current construction methods or product choices.

If a builder is already incorporating sustainable building practices into their daily work, making small changes such as utilizing structural continuous insulation can go a long way. Doing so can earn them a spot as a go-to sustainable builder in their community where they can tout the fact that they meet the most stringent standards in residential homebuilding. And of course – for at least the next 10 years – they will receive significant annual tax credit reimbursements for doing their part to create a greener built world.